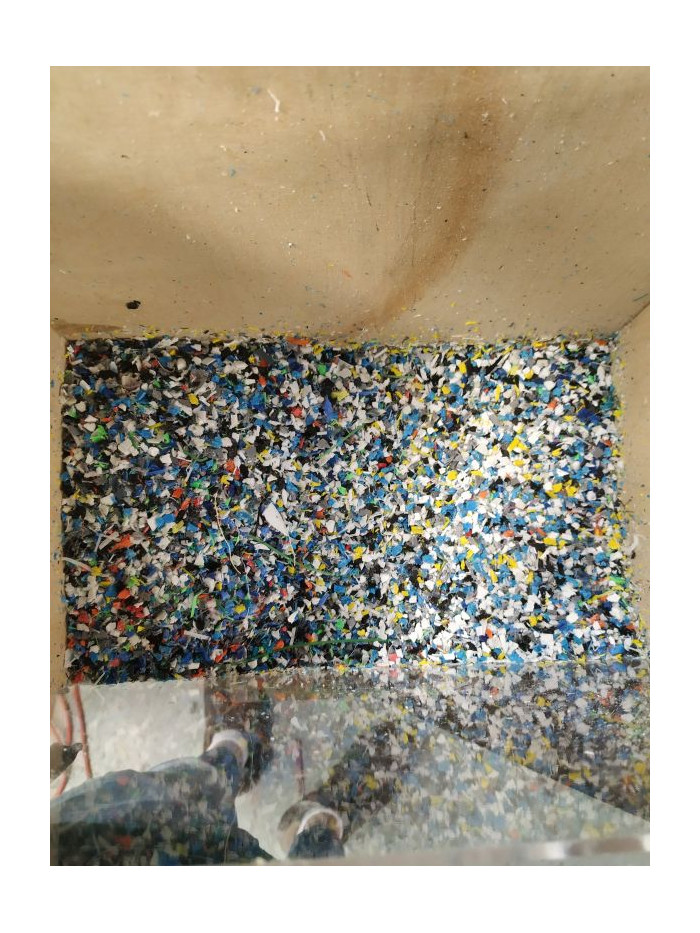

We are building Shredders fully automated with 3HP. The Shredder allows you to shred the plastic into small flakes to later be able to re-shape it or process it.

We have been doing some Shredders in the past, and we readapted a bit the machine to make it safer and to be able to make it more versatile for schools, institutions, or workshops.

We did a small redesign of the original shredder to adapt it. We added a VFD ( Variable Frequency Drive ) to control the motor and the load that is applying to all the components. The VFD allows us to automatize the movement of the motor. If we put too much plastic into the shredding unit and the motor feels that there is too much pressure being applied, it will automatically reverse its direction and do a clearing maneuver until it continues to grind with adequate pressure. This allows you to not have to worry or keep reversing the motor direction to unblock the machine and have an automated continue shredding process.

Aside from the VFD we also incorporated different safety gadgets to make the machine completely safe for all kinds of users, even first-time users with no knowledge of the process of shredding. These safety components are:

1. Magnet sensor on the top door, to immediately stop the machine when the user opens the door. This is really convenient due that the user doesn't have to remember to stop the machine before opening de door, and have chunks of plastic jumping around and risking them.

2. We incorporated an emergency switch as an extra layer of protection. Is difficult to make something dangerous with these safety components, but in case something will happen, this button will stop the machine immediately.

3. Due that the machine has a VFD, we are also limiting the load that the motor can apply, to protect the coupling, and the shredding box from getting damaged, deformed or destroyed by the pressure that the motor applies to it. The load is limited according to the loads that the set of parts of the machine can bear.

4. The machine has a key to enable it or switch it on, so nobody can switch on the machine without the key of the machine.

5. We added a led pilot, to know that the machine is on.

The machine comes assembled and tested, ready for use.

Maintenance, safety, and use instructions provided.

MOTOR:

2.2KW - 3HP - 1500RPM 100L4A /28mm

GEARBOX:

Gearbox RSTV90 /E-28mm / S-35mm i = 1:25

COUPLING:

Lovejoy L-150 20x35 HYTREL

CONTROL BOX:

- Reset Button

- Key switch

- Magnetic door switch

- 3 position switch // FWD, REV, 0

- Emergency switch

- Pilots LED

- Thermal protection 16A

- 5M Cable 220V 16A

Comes with hopper and collection box!

These machines are dangerous and must be used with personal protection equipment. The manufacturer could not be held as responsible in case of accident or injuries.

...

Domestic shipping to

This seller doesn't have any reviews yet