Combo Unit - Sheet Press Machine & Shredder (V3)

We provide virtual sessions to run the machine efficiently. It also offers free complete technical support, installation, and virtual training upon receiving the machine.

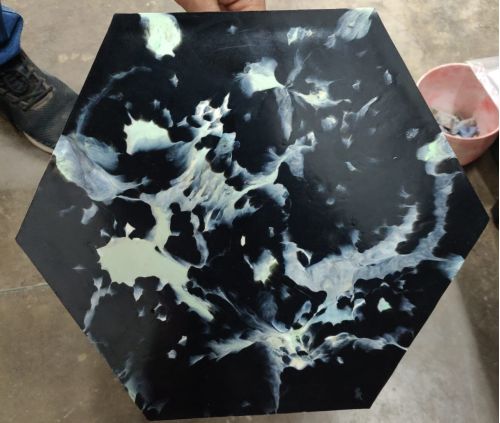

30 CM Hot press + Cold Press Setup + Free Mould (CE Certified & Factory Made)

IT ALSO INCLUDES A FREE MOULD OF 12MM THICKNESS

Sheet Press Machine

SPECIFICATIONS:

• WORKING AREA FOR HOT PRESS AND COLD PRESS: 350 X 350 X 120 MM

• ALUMINIUM PLATE THICKNESS: 8 MM

• TEMPERATURE CONTROLLER: 2 Nos. (MULTISPAN)

• POWER SUPPLY: SINGLE PHASE 220 VOLT

• INITIAL POWER LOAD: 2 Kw (Approx.)

• PRESSURE: 3 TONN JACK

• 4 SUPPORTING SHAFTS WITH LINEAR BEARING

• OUTPUT: 3 – 25 MM SHEET (TESTED)

• HEAVY FRAME FOR STABILITY

This machine can make multiple sheets from HDPE / PP / PS / LDPE.

Custom-size machine is also available.

Let's solve this plastic problem together.

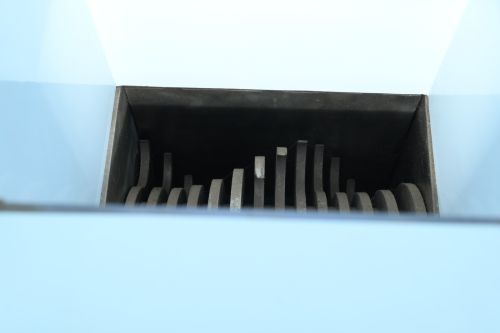

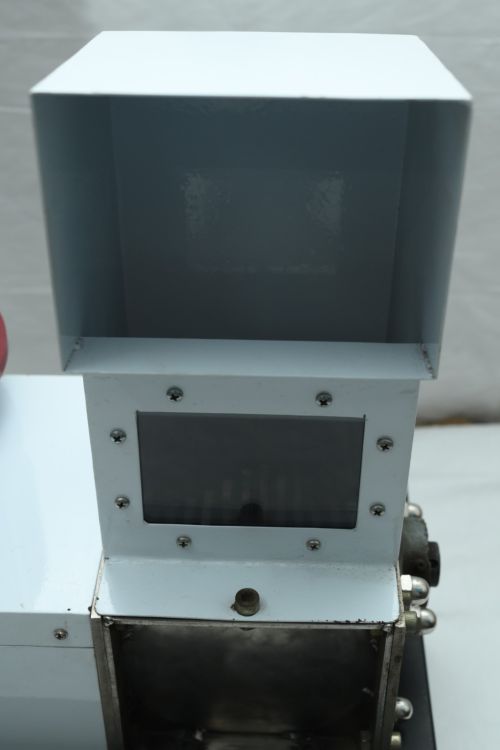

Shredder Machine (V3)

DESIGN PARAMETERS WITH STANDARD SUPPLY:

- 2 HP Single Motor

- Gearbox NMRV90 1:30

- Shredder Body

- Other Supporting systems

SPECIFIC DATA:

- Dimensions: 600x300x1200 mm

- Max. Production Output: Depending upon the material

- Hopper Loader: M.S. Fabricated Hopper

- Structure: MS fabricated heavy‐duty structure made from angles, and channels and Covered with sheet

- Single axes Shaft of EN 8 Blades with hardox

Electrical:

- Forward and reverse control with the Emergency button.

- Power supply: Single Phase 220V/ Three Phase 400V/50Hz

- A Multifunction Emergency switch is located on the machine and control panel.

- Power Consumption is 1.5 kW