About Andy’s Recycling Machines

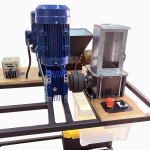

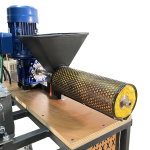

Andy's Recycling Machines, based in Santa Cruz de Tenerife, Canary Islands, Spain, I make the pallet sized MultiMelt Machine, with the Extruder, now with Arbor Injector and either the Compressor Oven, or the Shredder, all together on a strong metal frame, easy to transport (as a pallet sized transport) and occupying half the space of the 3 machines by themselves, small enough to fit in almost any place (standard pallet size = 80cm x 120cm)... if you have a small workshop then this format is ideal

I also make one-off machines, the Shredder, Arbor Injector, Extruder and Compressor Oven ;-) Interested? Questions? Send me a message with the "Contact Seller” button

MultiMelt Machine, 3-in-1 compact frame recycling system for small workshops

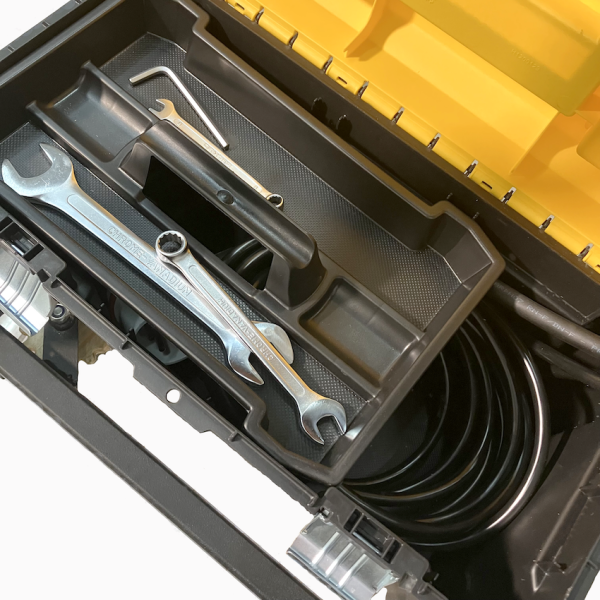

Once I'd made my first set of Precious Plastic Machines, I quickly realised they take up a lot of space between them all! So I designed a compact frame MultiMeltMachine that takes up half the space of the 3 incorporated machines, and as a bonus is more stable than any stand-alone machine, as the combination is heavier ;-) I also wanted to include somewhere to store all useful tools, small moulds, cleaning and maintenance stuff, etc, instead of having that stuff spread around the workshop, so I also included a small storage area - all in all a well thought out solution to smaller workspaces.

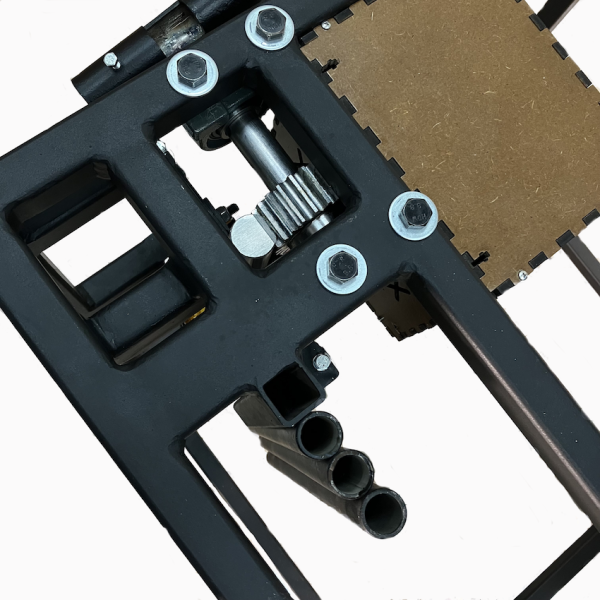

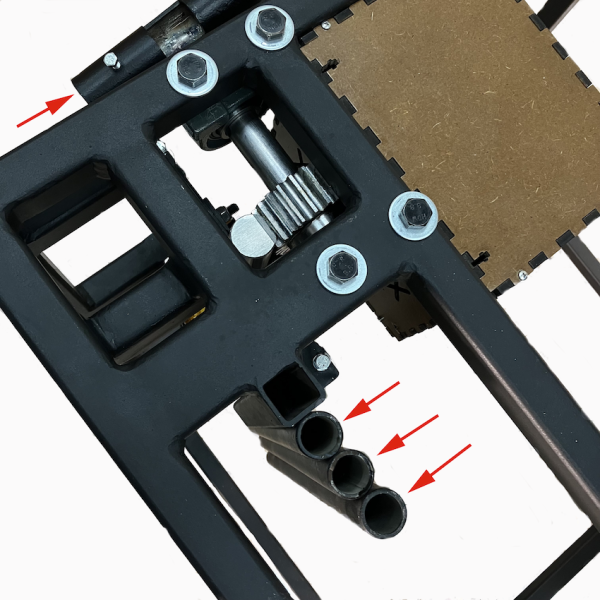

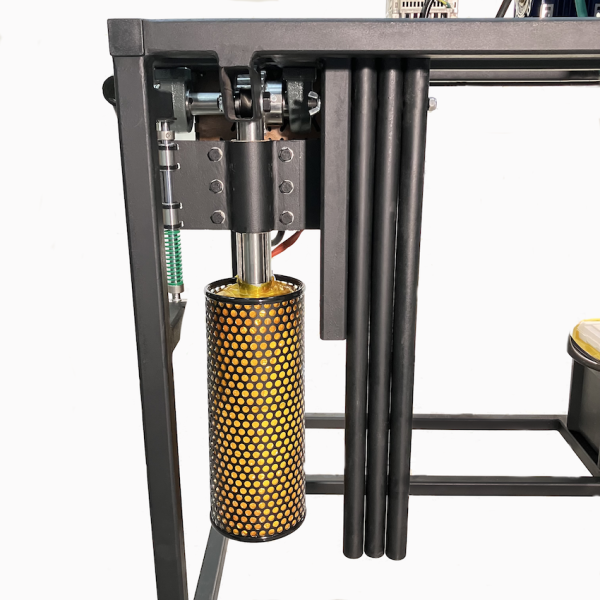

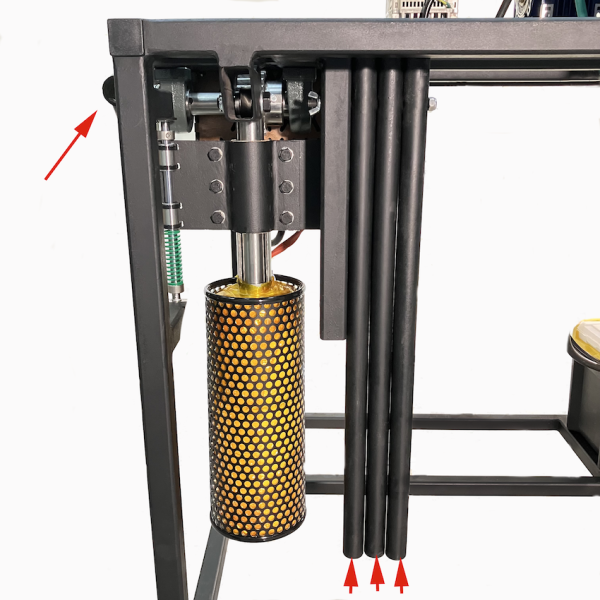

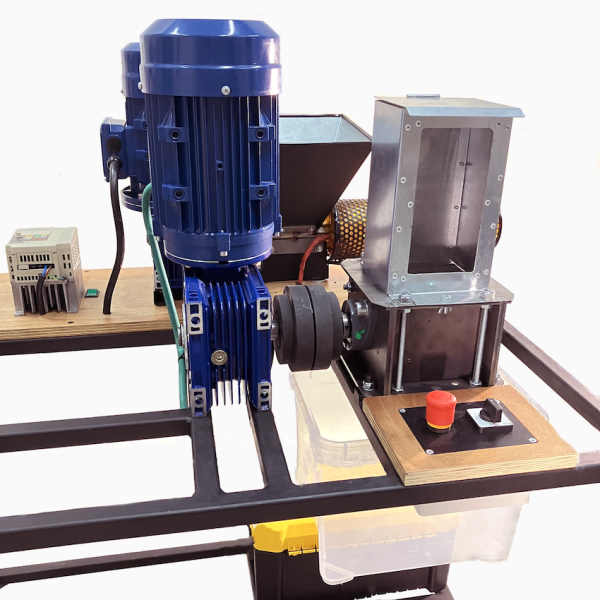

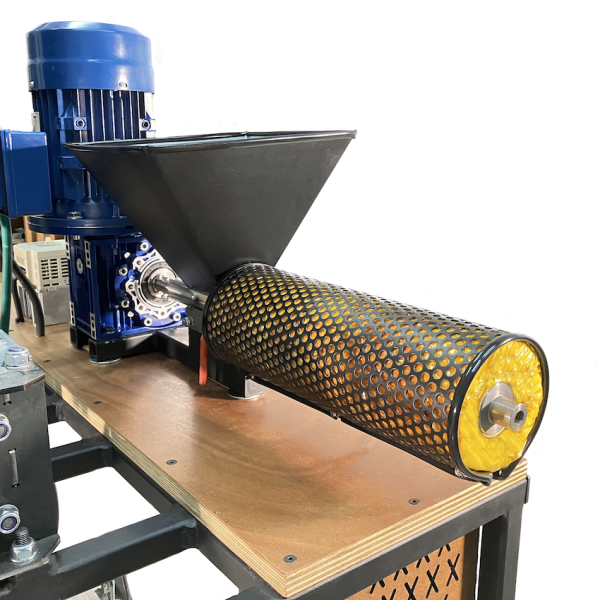

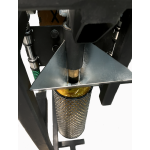

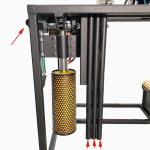

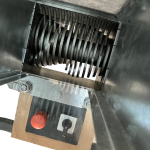

Compact Multi Melt Machine based on easily transportable pallet sized (120cm x 80cm) frame, containing Extruder, Injector, and Shredder. Frame has lowerable wheels for easier moving around the workshop (although should be used with wheels raised!!), and comes with an attached metal storage area, consisting of lockable drawers (depending on availability, the original draw set was discontinued at my hardware store!).

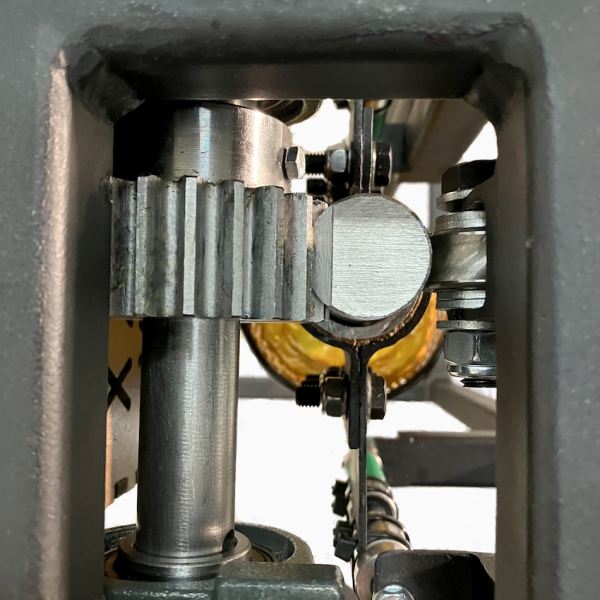

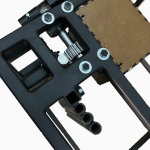

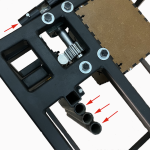

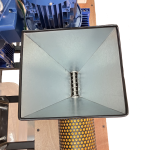

For transport purposes, the Extruder can be moved back so the nozzle is behind the nearest edge; during use will be moved forward to hang over the edge and have good clearance to the nozzle - now with Arbor Injector, 6x more injection pressure can handle moulds that where impossible to fill with previous version… handle levers, hub and axle have been carefully designed and measured so as to fit into recesses in the machine (screwed down) so they also do not pose a problem during transport.

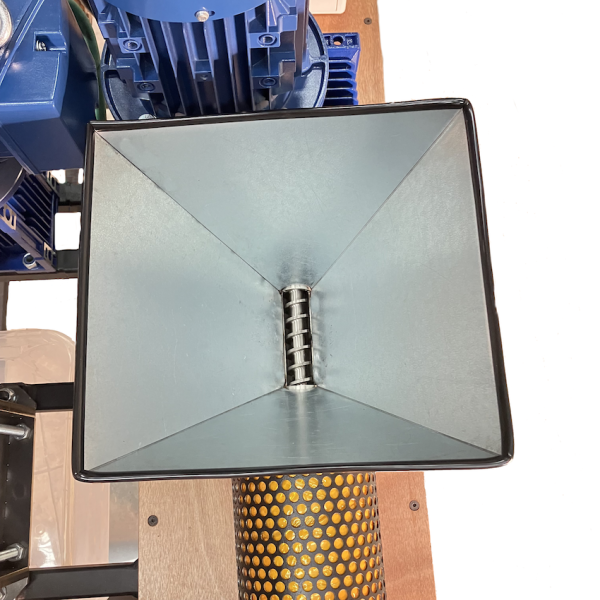

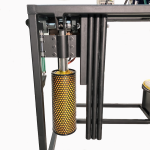

Extruder and Injector have 50mm ceramic wool insulation, for next level heating efficiency, Injector also has cork lined clamp system, to isolate any heat passing to the frame, and Injector comes with Spring-Loaded Barrel for Quick Sealing of moulds, no need to screw and unscrew moulds any longer*, the seal is automatic on positioning and injecting!! Faster mould filling means less blockages from cooling plastic ;-)

* you will require to make your own wood support blocks, that have to go under the mould when injecting, each size of mould will require its own sized wood support block

Machines made under order, please give about 2 months for complete preparation of the frame and 3 machines to be integrated, sourcing the materiales here in Canary Islands take take a little longer than other places ;-)

Shredder requieres a 5 pin 3 phase 380v electrical line, the rest of the machines use 220v

Version with Compressor Oven (but WITHOUT Shredder) only uses 220v

Features:

- Most compact format for 3 Basic Precious Plastic machines!

- Extruder screw and motor have common frame to maintain rigidity, slides back during transport

but during use hangs over the table edge for easier use

- Extruder (2kW), Injector (1kW) and version with Compressor Oven (2kW) use single phase electricity

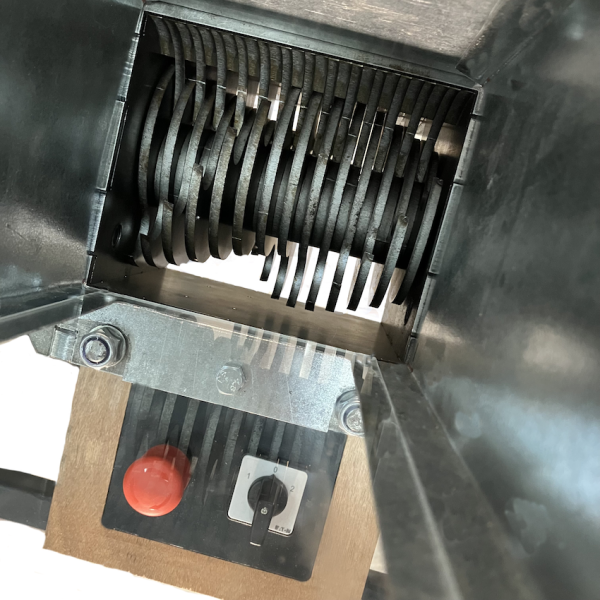

- Version with Shredder uses 2.2Kw 3-phase motor for more powerful shredding

- Pallet Size Frame approx 120x80x140cm, 150kgs, can be easily loaded onto van by 4 people,

and has wheels for occasional transport

- New change: Injector now with Arbor press system, 6x more injection pressure! Handles,

hub and axle designed to stow away for transport

- Injector with cork lined clamp system (for better heat isolation from frame, more efficient heating)

and Spring-loaded barrel, for quick sealing and release of moulds

- Extruder with M12 screw for nozzle tips, provided with starting set of 4, 6 and 9mm round holes

- Injector provided with initial 5.5mm nozzle, nozzle to barrel union is 1-1/4” standard imperial BST

fittings, so can easily make new nozzles as per your own requirements/ designs

- Storage area for all tools (provided with set of required spanners, etc) cables, some moulds, etc

- Version WITH COMPRESSOR OVEN comes WITHOUT Shredder (only can fit 3 machines

on this size frame)

Shipped FROM CANARY ISLANDS, SPAIN:

For EU, own transport & pick up, otherwise I will give you our best local transport contact here, I CANNOT fiscally arrange shipping or import tax to Europe, it must be arranged from your end

Domestic shipping costs to Spain are approximate, example is Madrid, contact for a correct quote; transport ONLY, import tax and customs dispatch NOT included (as must be billed and paid for by receiver)

Item location

- Santa Cruz de Tenerife

- 6-8 weeks

- Free

Domestic shipping to

- One item: €416.00

- Each additional item: €0.00

This seller doesn't have any reviews yet